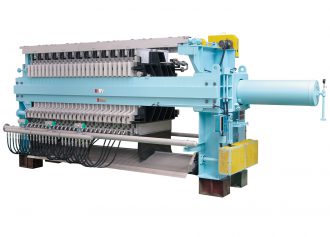

LASTA SD is a horizontal filter press, designed to meet the ever increasing demands of various customers for slurry dewatering.

ISHIGAKI LASTA SD is able to provide perfect cake discharge, efficient cloth wash and short cycle time.

FEATURES

ISHIGAKI LASTA Presses are widely used by many industries in various applications

where “Low Moisture Content” process dewatering is required. The ISHIGAKI LASTA

Press is a Fully Automatic filter press with many unique features.

Fully automatic operation, perfect cake discharge

High Performance and compact dewatering pressure filter

Effective and efficient cake washing

Technical feature

Patents:

100 Registered and Pending Patents in Japan and Internationally, including the UK, USA, Germany and France

Awards:

1973 Special Recognition by the Japanese Ministry of International Trade; Excellent Pollution Prevention Machine;

Prize of Industrial Science and Technology by the Director

General Agency; Excellent Energy-Saving Device;

President’s Prize from the Japanese Machinery Federation

Quality Certified: ISO9001 and ISO14001 Approved

Installations: There are more than 1000 installations world-wide in many industries and applications

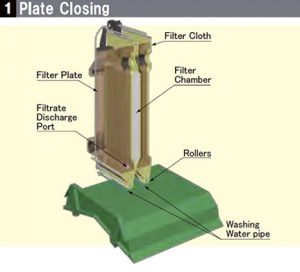

1. Filter plate pack close

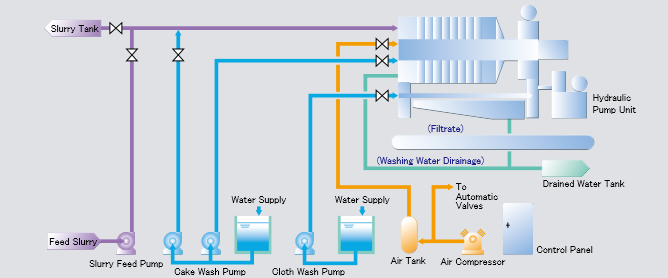

After activating the start switch, the hydraulic power pack pumps oil to the hydraulic cylinder which clamps all the filter plates together and forms each filtration chambers.

2. Filtration

Slurry is pumped via the feeding port to the filtration chambers. The solids remain and the filtrate passes through the filter cloth.

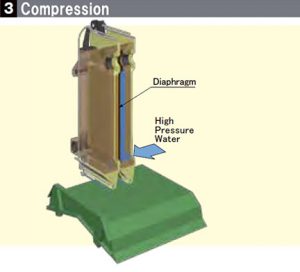

3. Compression

Pressurized water is jnjected behind the diaphragms. The filter cake is compressed and further dewatered.

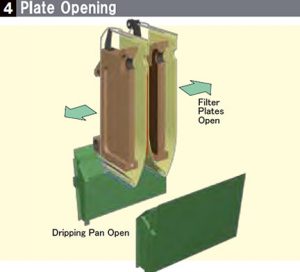

4. Filter Plate Pack Open

After completion of filter cake compression process, the hydaulic pump operates automatically for driving cylinder and opening the filter plate pack.

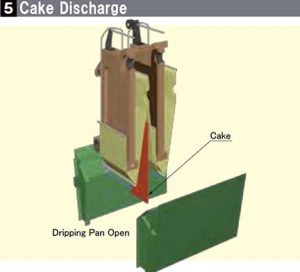

5. Cake Discharge

When all the filter plates are opened, all the filter cloths containing discharged cake travel downwards and filter cake is discharged.

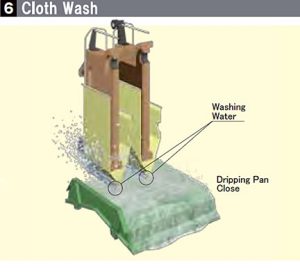

6. Filter Cloth Washing

After the filter cakes are discharged, the cake doors close and all the filter cloths are washed on the return travel.

Compression Pressure (Diaphragm)

| MODEL | PRESSURE |

| L | 0.7 MPa |

| H | 1.5 MPa |

| R | 2.0 MPa |

| S | 2.9 MPa |

Material option

Standards LASTAs

Frame: Structural steel and stainless steel

Filter plate: PP

Diaphragm: rubber

Other materials are available to suit customers’ requests.

Cake wash system

Wash water passes through the filter cake, foreign substances in cake are removed or precious substances in case are extracted.

Normal cake wash: Wash water is fed into each chamber from the top feeding port, passing through the cake and discharged via the filtrate port.

Back cake wash: The wash water is fed from filtrate port of one plate, it passes through the cake and then discharged from the filtrate port of the next plate.